MES

The mHub module to optimize your manufacturing processes

COMPLEX BECOMES SIMPLE

Traditional functionalities

improved and expanded

The traditional Manufacturing Execution System has received a facelift with this module. The large number of well-known MES functionalities can now be operated quickly and easily from both the office and the shop floor. Large amounts of data can be processed via a remarkable, responsive user interface that has been perfected over time by a team of accomplished UX designers. Complex processes and slow revisions are a thing of the past, simple transformations and changes at the push of a button are the present.

WHERE IT IS USED

Use cases & business units

Production

Management

Quality Assurance

Logistics

Maintenance

Controlling

WHY MES

Advantages overview

TRANSPARENT PRODUCTION

Data recorded during production is available at all times. From any connected device, in real time.

DATA COLLECTION OF INFLUENCING FACTORS

Accurate and immediate capture of unplanned factors to avoid or reduce production delays.

OPTIMIZATION BASED ON HOLISTIC DATA

The collection and analysis of data from all points of the production cycle, helps process optimization.

OEE METRICS AND DASHBOARDS

Data analysis is always available in organized dashboards dynamically adapted to any screen size.

CENTRAL DATA ENTRY AND DISPLAY VIA TERMINALS

Convenient data procurement from a variety of sources ensures it is available where it is needed - on the shop floor, during production.

MODULE DESCRIPTION

What is our MES?

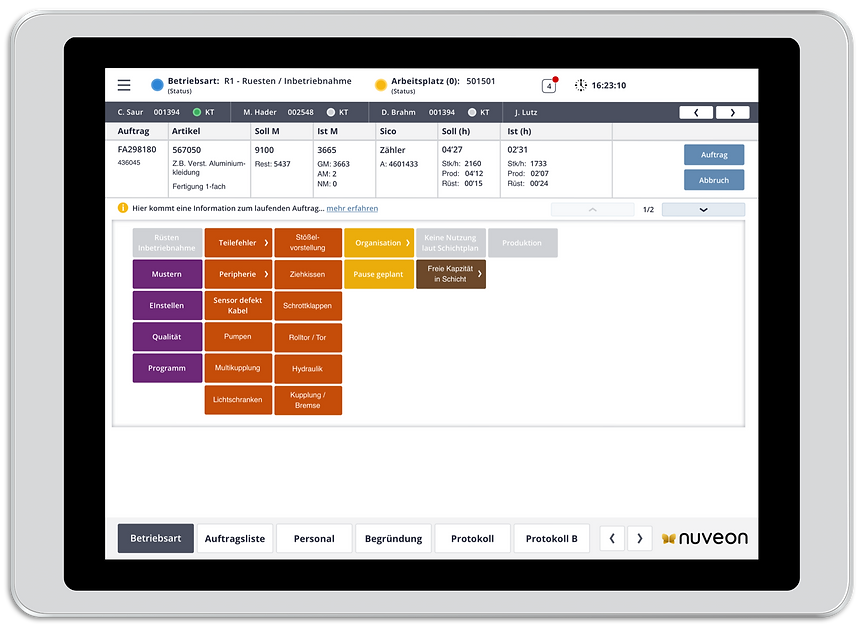

The main advantages of the nuveon MES module are accessibility and flexibility. A control-center area allows an executive or a manager to enter and manage data, adjust processes (e.g. posting reasons for plant terminals), view the status of manufacturing systems, analyze KPI dashboards or OEE metrics and much more. At the same time, relevant data is made available on the shop floor terminals. This includes the typical production functions such as: machine data acquisition, production data acquisition, personal data collection, tool management, production notifications with label printing, booking journals, order backlog based on production planning and many more. UX design specialists are always involved to arrange large amounts of data in an understandable and concise manner while ensuring integrity remains intact through different screen types and sizes.

Lay cards on the.. dashboard

Let's be honest, with so many components needed for a holistic MES, organization from the start is essential! Color-coded cards are the answer.

Planning has never been easier

A consistent filter layout at the top of the page makes for an intuitive interface. Contrast, layout and clear conflict indicators lead to error-free planning.

Enjoy data

Not only is the intuitive and familiar filter function present, but also clear color-coded charts show the production status. Everything worth knowing at a glance.

Yep! Cards help...

Another data set organized to process a large amount of information at a glance. Status circles and highlighted errors help identify problems quickly.

On the shop floor in production

Particular attention was paid to the design of the machine-terminal interface. Large buttons, rich colors, clear data breakdown and more. Wait until you see the other terminal pages...